After 20 years of deep cultivation in the electronic component manufacturing industry, I have witnessed every innovation in the LTCC production process. When I visited an electronic component factory in Shenzhen last year, their production supervisor told me an amazing number: after the introduction of YSR Automatic LTCC Stacking Machine, the product defect rate dropped from 3.2% to 0.5%, which made me more convinced of the importance of automated equipment for precision manufacturing.

When I visited an electronic manufacturing company in Jiangsu last month, the technical director showed me shocking comparative data: manual stacking can complete up to 800 layers per shift, while after adopting YSR Automatic LTCC Stacking Machine, the single machine capacity is directly increased to 5,000 layers/shift. This is thanks to our innovative visual positioning system, with a positioning accuracy of ±5 microns.

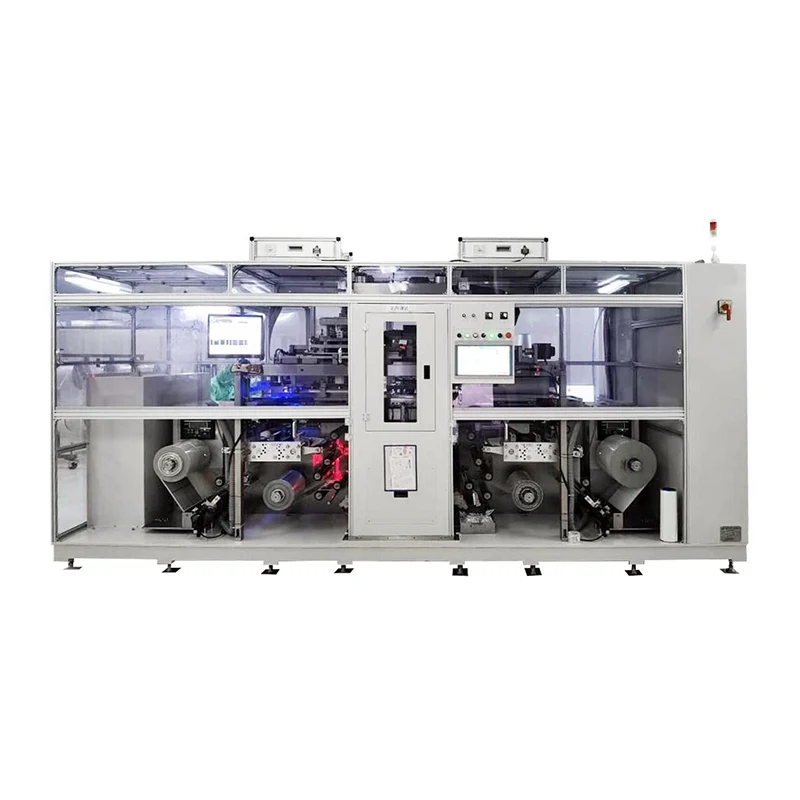

Through the experience of serving hundreds of electronic manufacturing companies, I have summarized three key indicators: the first is stacking accuracy. Our Automatic LTCC Stacking Machine has a repeat positioning accuracy of ±2 microns; the second is production efficiency, with a maximum speed of 1.5 seconds/layer; and the last is compatibility, which can adapt to substrates of various sizes from 5×5mm to 150×150mm.

The production manager of a military electronic company shared an important discovery: since adopting our Automatic LTCC Stacking Machine, not only has the product consistency been significantly improved, but more unexpectedly, it has obtained the qualification of a second-tier supplier of an international giant. This proves that the accuracy of the equipment directly affects the market competitiveness of the enterprise.

When evaluating equipment for an electronics factory in Zhejiang recently, it was found that the thickness difference of their products caused by their manual stacking process was as high as 8%, which seriously affected the subsequent process. Each YSR device undergoes a 72-hour continuous operation test before leaving the factory to ensure stable and optimal performance at the customer's site.

The case of a newly built 5G component factory in Guangdong is very convincing. They chose the YSR Automatic LTCC Stacking Machine in the planning stage, not only reaching full production two months ahead of schedule, but also reaching the industry-leading product yield. If you are considering upgrading your production line automation, our engineers are ready to provide you with professional solutions.

Our products are very reliable. If you have any needs, please feel free to contact us. We will provide you with efficient solutions online 24 hours a day.