1. Overview of Multilayer Ceramic Technologies

Multilayer ceramic technologies are foundational to modern electronics manufacturing. Three primary variants dominate the field:

· MLCC (Multilayer Ceramic Capacitor)

· LTCC (Low-Temperature Cofired Ceramic)

· HTCC (High-Temperature Cofired Ceramic)

Their distinctions lie inmaterial selection,sintering temperatures,process details, andapplication scenarios.

2. Technical Specifications Comparison

|

Parameter |

MLCC |

LTCC |

HTCC |

|

Dielectric Material |

Barium Titanate (BaTiO₃), TiO₂, CaZrO₃ |

Glass-Ceramic, Ceramic-Glass Composite |

Al₂O₃, AlN, ZrO₂ |

|

Metal Electrodes |

Ni/Cu/Ag/Pd-Ag (internal); Cu/Ag (terminals) |

Ag/Au/Cu/Pd-Ag (low-melting alloys) |

W/Mo/Mn (high-melting metals) |

|

Sintering Temp. |

1100–1350°C |

800–950°C |

1600–1800°C |

|

Key Products |

Capacitors |

Filters, Duplexers, RF Substrates, Antennas |

Ceramic Substrates, Power Modules, Sensors |

|

Applications |

Consumer Electronics, Automotive, Telecom |

RF/Microwave Circuits, 5G Modules |

Aerospace, High-Power Electronics |

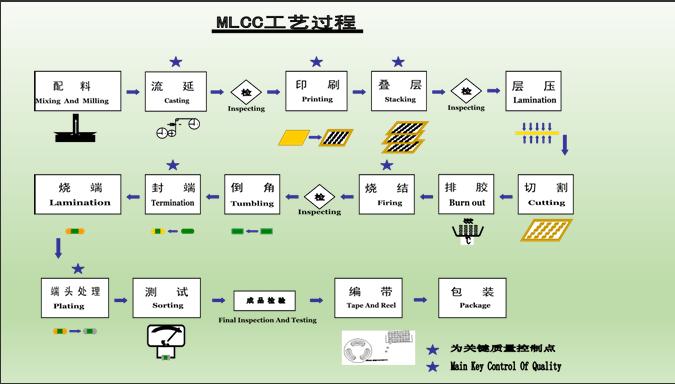

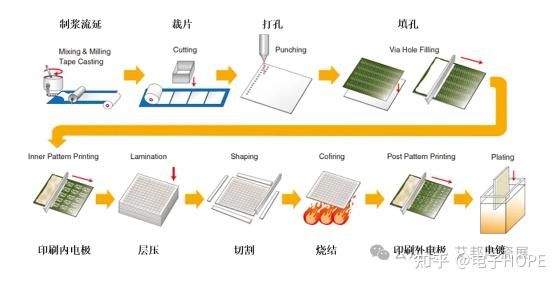

3. Manufacturing Process Flow

Shared Core Steps:

1. Tape Casting: Forming green ceramic sheets (thickness: 10–100μm).

2. Screen Printing: Depositing electrode patterns (e.g., Ag paste for LTCC, Ni for MLCC).

3. Lamination: Stacking layers under pressure (20–50 MPa).

4. Sintering: Firing in controlled atmospheres (N₂/H₂ for MLCC, air for LTCC/HTCC).

5. Termination: Applying external electrodes (e.g., Ag plating for MLCC).

Critical Differences:

· Via Drilling: LTCC/HTCC require laser-drilled vias for vertical interconnects; MLCC skips this step.

· Sintering Atmosphere:

· Layer Count:

4. Performance Trade-offs

|

Metric |

MLCC |

LTCC |

HTCC |

|

Capacitance Density |

100 μF/cm³ (X7R-grade) |

N/A (non-capacitive focus) |

N/A |

|

Thermal Conductivity |

3–5 W/m·K |

2–3 W/m·K |

20–30 W/m·K (AlN-based) |

|

CTE Matching |

Poor (vs. Si) |

Moderate |

Excellent (Al₂O₃ ≈ 7 ppm/°C) |

|

High-Frequency Loss |

Tan δ < 2% (at 1 MHz) |

Low insertion loss (<0.5 dB @ 10 GHz) |

Stable up to THz frequencies |

5. Emerging Innovations

· Ultra-High Layer MLCC: TDK’s 0.4μm-layer technology achieves 220μF in 0402 packages.

· 3D LTCC Integration: Kyocera’s embedded passives reduce RF module size by 60%.

· HTCC for Extreme Environments: CoorsTek’s AlN substrates withstand 1000°C in aerospace sensors.

Conclusion: MLCC, LTCC, and HTCC technologies address distinct needs across the electronics spectrum. MLCC dominates miniaturized passive components, LTCC enables compact RF systems, while HTCC excels in harsh-environment applications. Process optimizations—from material science to via architecture—drive their continued evolution in 5G, EVs, and advanced aerospace systems.