HTCC (High-Temperature Co-Fired Ceramic) machine refers to ceramics sintered at temperatures exceeding 1,000°C, typically using materials such as alumina or aluminum nitride, with firing temperatures generally above 1,500°C. These ceramics are co-fired with high-melting-point metals (e.g., tungsten or molybdenum) in high-temperature furnaces.

LTCC (Low-Temperature Co-Fired Ceramic) machine, on the other hand, incorporates glass powder into the ceramic slurry to introduce a glass phase, enabling sintering at temperatures below 950°C. This process allows the integration of through-hole materials, thick-film electrodes, interconnects, and passive components into a multilayered structure during a single low-temperature firing.

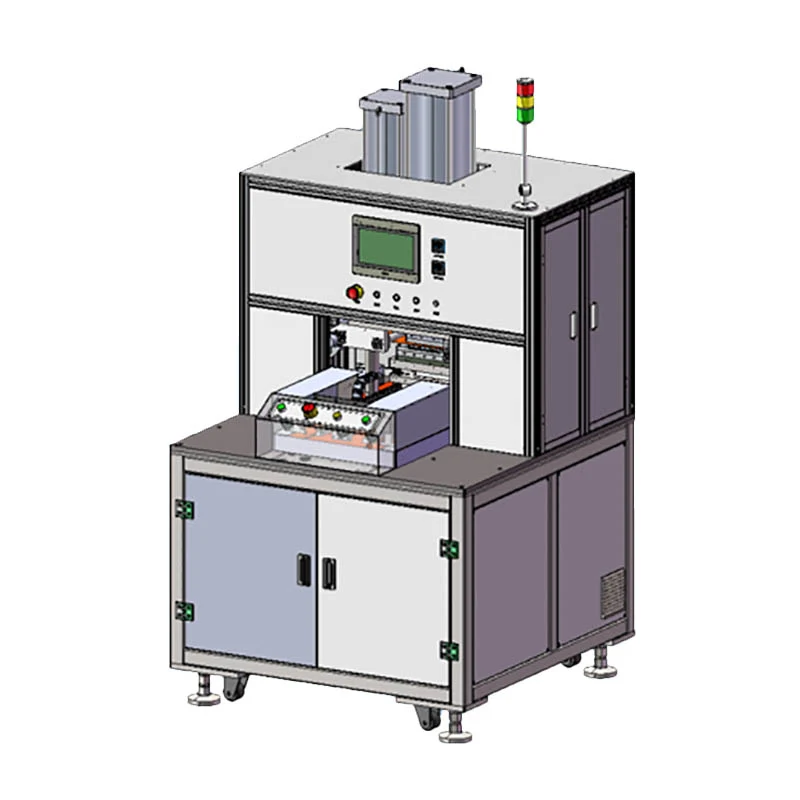

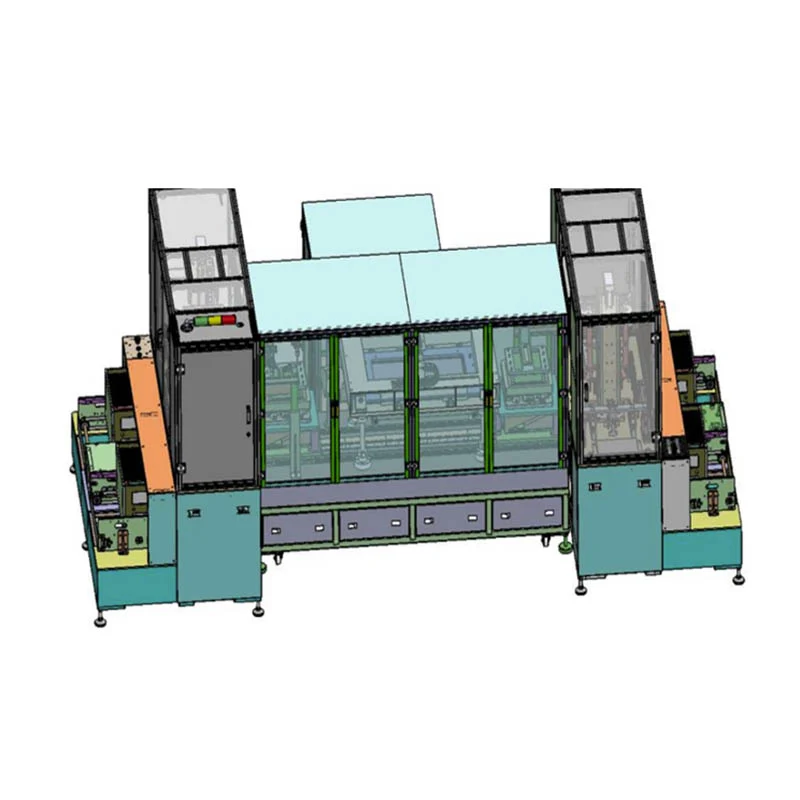

Yisenrong Technology Co., Ltd., located in the Xiamen Free Trade Zone, China, leverages its technological strengths to build a comprehensive semiconductor equipment supply chain integrating R&D, design, and production. Yisenrong’s intelligent HTCC products—including the HTCC Isostatic Press, HTCC Flattening Machine, and HTCC Frame-Integrated Automatic Printing Machine—are best-selling products. These solutions not only deliver high efficiency, productivity, and functionality but also help clients achieve cost advantages and greater economic value in the current economic landscape.

Opportunities for HTCC Machine:

· Sustained Market Demand Expansion

· Technological Innovation and Process Breakthroughs

· Policy Support and Industry Chain Synergy

Challenges for HTCC Machine:

· Technological Barriers and R&D Investment Pressures

· Cost Pressures and Intensified Market Competition

· Environmental and Sustainability Requirements

Future Trends:

· Intelligent and Automated Production: Integration of AI-driven quality control and digital twin technologies.

· Cross-Domain Integration: Complementary use of HTCC and LTCC technologies (e.g., hybrid co-firing processes) to expand into emerging fields such as medical electronics and optical communications.

· Green Manufacturing: Development of low-temperature co-firing compatible materials (e.g., silver paste replacing tungsten paste) to reduce energy consumption and pollution.