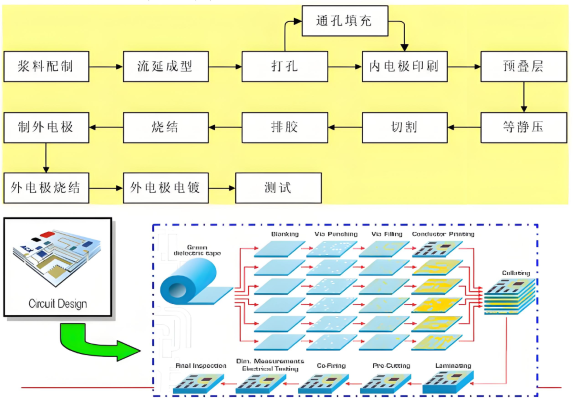

The core process of LTCC technology is as follows: First, ceramic powder, glass powder, and organic binders are mixed, and then processed into green ceramic tapes with precise thickness and dense structure through tape casting, drying, and other processes. Subsequently, the required circuit patterns are fabricated on the green ceramic tapes using technologies such as laser drilling, micro-hole grouting, and precision conductor paste printing. Next, multiple processed green ceramic tapes are laminated and integrated, and sintered in a low-temperature environment below 900°C. Finally, chip devices can be produced; it can also embed multiple passive components to form a single three-dimensional ceramic multilayer circuit substrate; in addition, ICs and active devices can be mounted on its surface to create passive/active integrated functional modules. This technology can further promote the miniaturization and high densification of circuits, and is particularly suitable for the manufacturing of components in the high-frequency communication field.

LTCC production process

In terms of material application, LTCC uses glass or ceramics as the dielectric layer of the circuit, and adopts metals with excellent conductivity such as Au, Ag, and Pd/Ag as the inner and outer electrodes and wiring materials.

The significant advantages of LTCC technology are reflected in the following aspects:

1. Low sintering temperature: The sintering temperature of LTCC materials generally does not exceed 900°C. This characteristic reduces the difficulty of the process, not only facilitating large-scale production but also effectively saving energy.

2. Adjustable dielectric constant: The dielectric constant of its materials can be flexibly adjusted within the range of 2 to 20,000, which can meet the design requirements of different circuits and greatly improve the flexibility of circuit design.

3. Excellent high-frequency performance: The ceramic material itself has excellent high-frequency and high-Q characteristics, and the operating frequency can be as high as several tens of GHz, fully adapting to high-frequency scenarios.

4. Superior conductor performance: Using metals with high conductivity such as Ag and Cu as conductor materials helps improve the quality factor of the circuit system.

5. Good temperature stability: It has favorable temperature characteristics, such as small thermal expansion coefficient and low temperature coefficient of dielectric constant, which can adapt to environments with temperature fluctuations.

6. Strong environmental adaptability: It can withstand large currents and high-temperature conditions, and its thermal conductivity is better than that of ordinary PCB circuit substrates, which can extend the service life of the circuit and improve reliability.

7. High wiring density: It can produce thin-line structure circuits with a line width of less than 50μm. While increasing the wiring density, it reduces the number of lead connections and solder joints, further enhancing the reliability of the circuit.

8. High integration level: It can produce underlying substrates with a large number of layers, and various passive components can be embedded inside, which can significantly improve the packaging integration level and realize the multi-functionality of modules.

9. Resistance to harsh environments: It has characteristics such as high temperature resistance and can work stably in harsh environments.

10. High production controllability: The non-continuous production process allows quality inspection at the green substrate stage, which is conducive to improving the yield and reducing production costs.

At present, LTCC products have been widely used in many fields such as 5G mobile phones, smart terminals, WiFi6 devices, 5G base stations, TWS earphones, and smart watches. With the continuous development of 5G/6G communication technologies, the demand for miniaturization, high-frequency, integration, and multi-functionality of devices is becoming increasingly urgent, and the importance of LTCC technology is becoming more and more prominent.