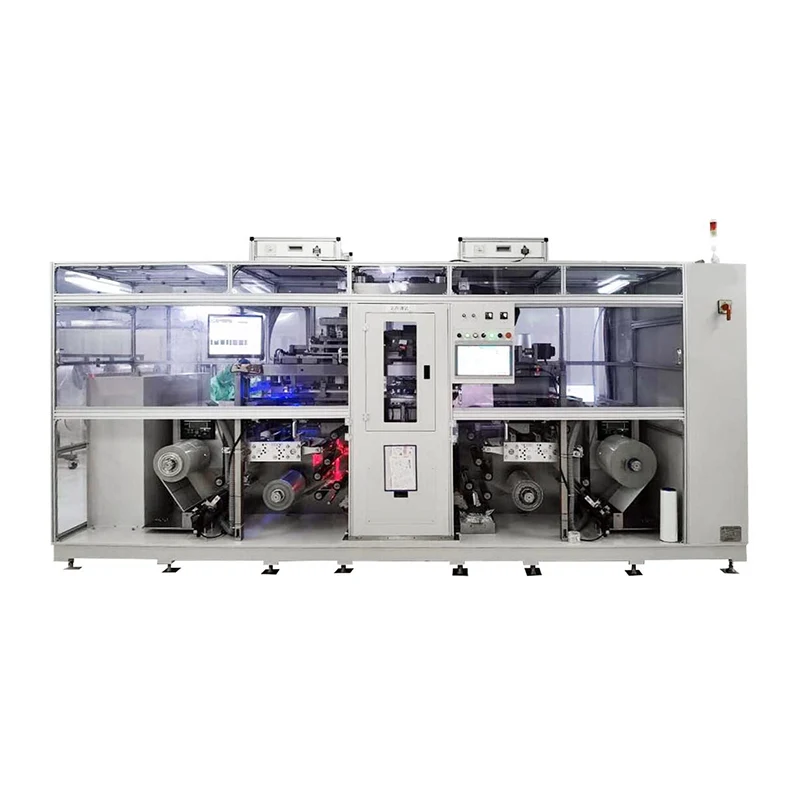

MLCC machines (Multilayer Ceramic Capacitor Machine) are automated equipment specifically used to manufacture multilayer ceramic capacitors. With the trend of electronic products towards miniaturization and high density, MLCC production equipment has also continuously improved its accuracy, speed and intelligence. In general, MLCC machines have the following significant characteristics:

1. High precision and high stability

- Extremely high dimensional control accuracy: In the processes of ceramic sheet pressing, cutting, lamination, etc., MLCC machines can achieve micron-level precision control to ensure consistent product thickness and number of layers and stable performance.

- Precise repeated positioning: For lamination and electrode printing processes, the positioning error is extremely small to ensure the consistency of the final product.

2. High-speed automated production

- Continuous operation design: MLCC production equipment usually has high-speed operation capabilities, which can achieve continuous printing, continuous lamination, and continuous cutting, greatly improving production capacity.

- Highly automated: From raw material feeding, molding, testing, sorting to packaging, fully automated operation is basically achieved, greatly reducing manual intervention and improving production efficiency.

3. Intelligent control system

- Automatic detection and feedback adjustment: Through the built-in visual inspection system or sensor, key parameters such as ceramic sheets, printing patterns, and lamination accuracy are monitored in real time, and abnormalities are automatically alarmed or corrected.

- Parameter programmable control: Different product specifications only need to adjust the set parameters through the program, with flexible switching to adapt to the production of various models of MLCC products.

4. Modular design

- Flexible configuration: Each module (such as printing, lamination, cutting, sintering, etc.) can be used independently or in combination according to production needs, which is convenient for expansion and upgrading.

- Easy maintenance: The modular structure makes equipment inspection and maintenance more efficient and shortens downtime.

5. Ultra-thin sheets and high-layer manufacturing capabilities

- As MLCC develops towards smaller size and higher capacity, modern MLCC equipment can handle extremely thin ceramic sheets (several microns) and can accurately stack hundreds or even thousands of layers, which puts higher requirements on mechanical precision and material compatibility.

6. Energy saving and environmental protection

- The new generation of equipment has also been optimized in terms of energy-saving design, waste gas treatment, and raw material recycling, reducing energy consumption and environmental impact in the production process, meeting green manufacturing requirements.

7. Adapt to a variety of process requirements

- Support thick film printing, lamination, isostatic pressing, cutting, sintering, terminal electrode processing, testing and sorting and other complete production processes, covering the production line requirements of different types and specifications of MLCC products.

In general, MLCC machines are characterized by high precision, high-speed automation, intelligent monitoring, and flexible configuration. They not only meet the needs of large-scale, high-quality production, but also continue to adapt to the development trend of miniaturization and high performance of electronic components. For companies that need to enter or expand MLCC production, it is crucial to choose advanced and reliable production equipment.

YSR Technology is a professional automated equipment supplier integrating R&D, design, manufacturing, sales, and service, specializing in intelligent semiconductor equipment manufacturing. You are welcome to buy our high quality products.Visit our website at www.ysrmachine.com to learn more about our products. For inquiries, you can reach us at ysrznzz@gmail.com.