HTCC (High-Temperature Co-Fired Ceramic) machine refers to ceramics sintered at temperatures exceeding 1,000°C, typically using materials such as alumina or aluminum nitride, with firing temperatures generally above 1,500°C. These ceramics are co-fired with high-melting-point metals (e.g., tungsten or molybdenum) in high-temperature furnaces.

LTCC (Low-Temperature Co-Fired Ceramic) machine, on the other hand, incorporates glass powder into the ceramic slurry to introduce a glass phase, enabling sintering at temperatures below 950°C. This process allows the integration of through-hole materials, thick-film electrodes, interconnects, and passive components into a multilayered structure during a single low-temperature firing.

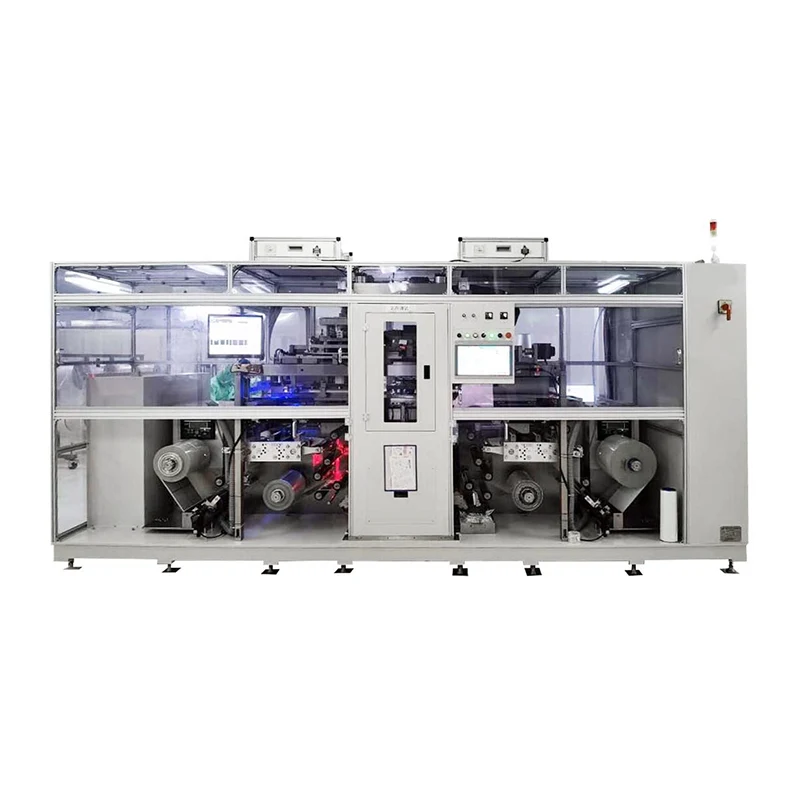

Yisenrong Technology Co., Ltd., located in the Xiamen Free Trade Zone, China, leverages its technological strengths to build a comprehensive semiconductor equipment supply chain integrating R&D, design, and production. Yisenrong’s intelligent HTCC products—including the HTCC Isostatic Press, HTCC Flattening Machine, and HTCC Frame-Integrated Automatic Printing Machine—are best-selling products. These solutions not only deliver high efficiency, productivity, and functionality but also help clients achieve cost advantages and greater economic value in the current economic landscape.

Opportunities for HTCC Machine:

· Sustained Market Demand Expansion

· Technological Innovation and Process Breakthroughs

· Policy Support and Industry Chain Synergy

Challenges for HTCC Machine:

· Technological Barriers and R&D Investment Pressures

· Cost Pressures and Intensified Market Competition

· Environmental and Sustainability Requirements

Future Trends:

· Intelligent and Automated Production: Integration of AI-driven quality control and digital twin technologies.

· Cross-Domain Integration: Complementary use of HTCC and LTCC technologies (e.g., hybrid co-firing processes) to expand into emerging fields such as medical electronics and optical communications.

· Green Manufacturing: Development of low-temperature co-firing compatible materials (e.g., silver paste replacing tungsten paste) to reduce energy consumption and pollution.

LTCC Machine Advantages:

1. Superior electrical/mechanical properties: High-frequency performance, temperature-stable resonant frequency, wide range of dielectric constants, and silicon-like thermal expansion coefficient.

2. High system stability and reliability.

3. Capable of fabricating 3D microstructures(e.g., cavities, channels).

4. High integration (sensors, actuators, microfluidic systems).

5. Excellent high-voltage and vacuum compatibility.

6. Low-cost manufacturing with short production cycles and high profitability.

Yisenrong Technology (YSR) is a professional automated equipment supplier integrating R&D, design, manufacturing, sales, and service, specializing in semiconductor intelligent equipment manufacturing. In the LTCC machine industry, YSR’s technical strengths and market applications include:

· Miniaturization and Integration: Reduced device size and enhanced circuit density for compact semiconductor equipment.

· High-Frequency Performance: Optimized signal transmission efficiency in high-frequency applications.

· High Reliability and Mass Production Compatibility: Compatibility with automated assembly processes and stable performance under extreme conditions.

Notably, YSR’s HTCC automatic cutting machines, HTCC flattening machines, and HTCC automatic coding machines have achieved industry-leading standards, delivering precision and efficiency for advanced ceramic component processing.

Technical Analysis and Applications of MCH Machine Heating Devices

I. Core Definition and Technical Advantages

MCH (Metal Ceramic Heater) machine is a metal-ceramic heating element formed by combining metal pastes (e.g., tungsten, molybdenum-manganese) with ceramics (e.g., 96% alumina) through a high-temperature co-firing process, resulting in a highly efficient and durable electrothermal component. Its technical advantages include:

· High Energy Efficiency

· Rapid Heating

· Eco-Friendly and Safe

· Long Lifespan and Stability

II. Key Application Areas

· Household Appliances: Instantaneous water heaters, smart toilets, and compact heating systems.

· Beauty Tools: Hair straighteners, curlers, and styling devices with precise temperature control.

· New Energy Vehicles and Industrial Equipment: Battery thermal management systems, industrial ovens, and high-power heating modules.

· Medical and Specialized Applications: Infrared therapy devices and aerospace sensors.

III. Market Landscape and Key Players

Global Market: The global MCH machine market reached a multi-billion RMB scale in 2023, dominated by leading players such as Analog Technologies and Induceramic.

IV. Yisenrong Technology in the MCH Sector

Yisenrong Technology specializes in MCH machine manufacturing equipment, including MCH cutting machines, MCH trimming machines, and MCH stacking machines, designed to enhance precision and production efficiency in ceramic heater fabrication.

Technical Analysis and Applications of RES Machine Resistor Devices

I. Fundamental Definition and Core Functions

RES (Resistor) machine devices are core electronic components designed to limit current and regulate voltage, with key functionalities including:

· Current control

· Voltage division

· Signal conditioning

II. Technical Features and Device Categories

1. High-Precision Adjustable Resistors

2. Industrial-Grade Resistivity Controllers

3. Intelligent Resistance Measurement Devices

III. Yisenrong Technology’s RES Machine Device Solutions

Yisenrong Technology specializes in RES machine manufacturing equipment, including:

· RES Stacking Machines

· RES Automatic Cutting Machines

· RES Frame Printing Machines

· RES Automatic Adhesive Sticking Machine

Classification:

· Continuous Sintering Furnaces

· Batch Sintering Furnaces

Key Parameters and Applications:

|

Parameter |

Typical Specifications |

Application Scenarios |

|

Temperature Range |

Ambient – 2200°C (e.g., vacuum graphitization) |

Carbon materials, refractory metal sintering |

|

Temperature Accuracy |

±1°C (Aidite’s compensation technology) |

Semiconductors, precision ceramics |

|

Atmosphere Control |

High-purity N₂/Ar (vacuum≤10⁻³ Pa) |

Oxidation-sensitive materials |

|

Production Efficiency |

Mesh belt furnace: 14 m/h line speed |

Automotive parts, powder metallurgy mass production |

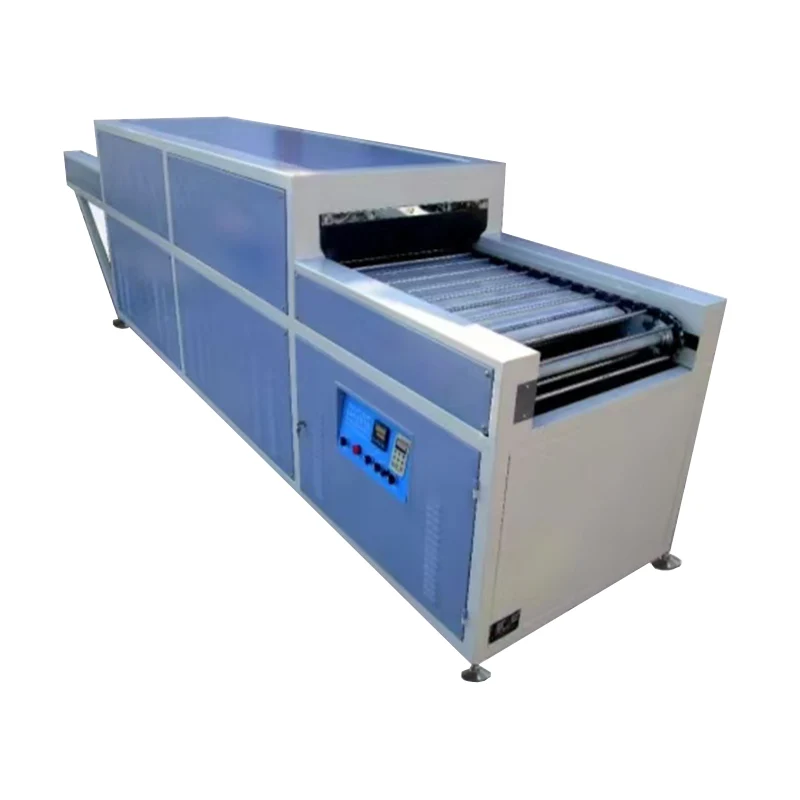

Yisenrong Technology specializes inlarge/medium industrial sintering furnace, including:

· Customized mesh belt and vacuum sintering solutions for high-volume manufacturing.

· Furnaces optimized for ceramic, metal, and composite material processing.