LTCC Machine Advantages:

1. Superior electrical/mechanical properties: High-frequency performance, temperature-stable resonant frequency, wide range of dielectric constants, and silicon-like thermal expansion coefficient.

2. High system stability and reliability.

3. Capable of fabricating 3D microstructures(e.g., cavities, channels).

4. High integration (sensors, actuators, microfluidic systems).

5. Excellent high-voltage and vacuum compatibility.

6. Low-cost manufacturing with short production cycles and high profitability.

Yisenrong Technology (YSR) is a professional automated equipment supplier integrating R&D, design, manufacturing, sales, and service, specializing in semiconductor intelligent equipment manufacturing. In the LTCC machine industry, YSR’s technical strengths and market applications include:

· Miniaturization and Integration: Reduced device size and enhanced circuit density for compact semiconductor equipment.

· High-Frequency Performance: Optimized signal transmission efficiency in high-frequency applications.

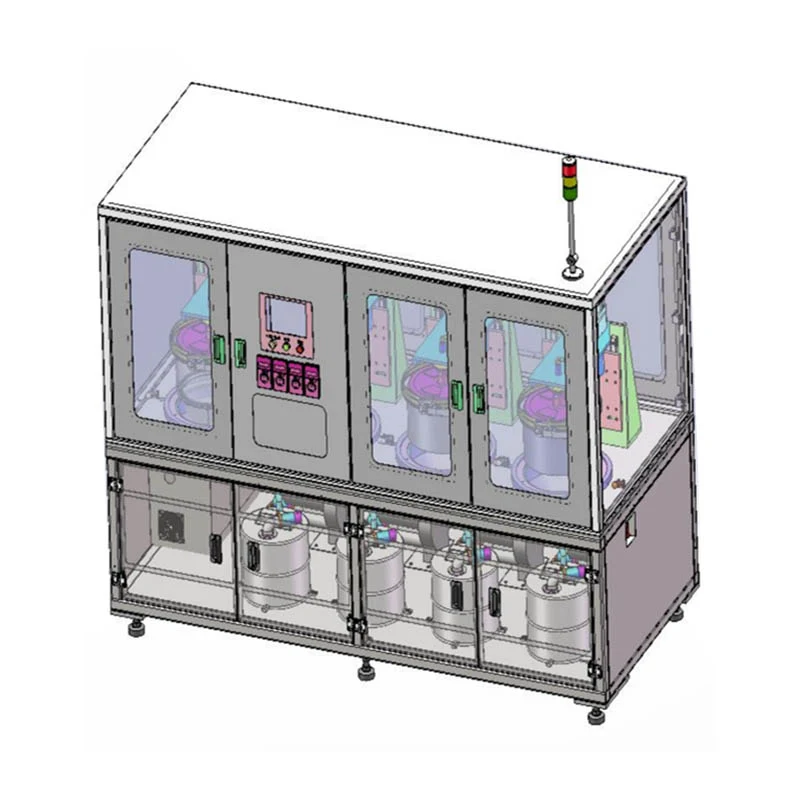

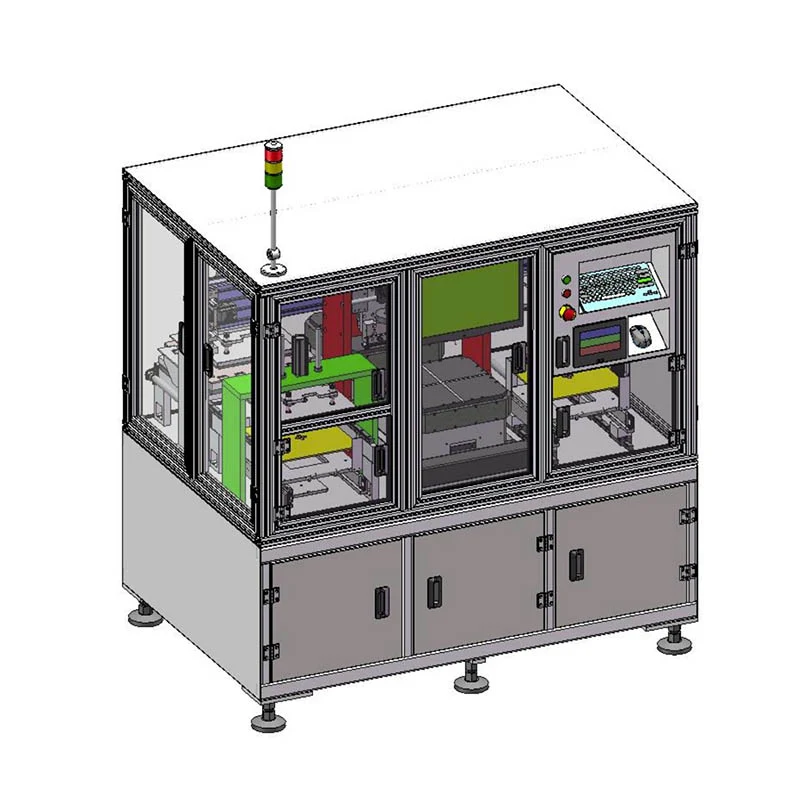

· High Reliability and Mass Production Compatibility: Compatibility with automated assembly processes and stable performance under extreme conditions.

Notably, YSR’s HTCC automatic cutting machines, HTCC flattening machines, and HTCC automatic coding machines have achieved industry-leading standards, delivering precision and efficiency for advanced ceramic component processing.